FAQ

-

What is Cable?

An energy & electric electrical current conveyance product, used in the areas of electric and electronic, coated with an isolating substance, and constituted by placing more than one metallic conductor (within the standards) inside. It is manufactured by coating with one or more wires or isolating substances, and used in all areas in our lives.

-

Which products do your quality and system documents cover?

-

Can we get information on the guarantee period of your cables?

Our cables are under 2 years of a guarantee starting from the delivery date for the errors arising from production. User errors, which might occur after delivery to the consumer, and errors to arise from a different utilization other than loading, transportation and normal utilization areas, are out of the guarantee coverage.

-

Can we get information on product development, product documentation, and Research & Development studies of your company?

Today, Erse Kablo is a trademark, which is preferred in many projects. This is a great responsibility. We make no concessions from behaving proper to this responsibility, and from standards and products bearing this responsibility. We will also continue to protect our image of reliable trademark which occurred in the minds of our customers since our establishment. Accordingly, Erse Kablo allocates a significant amount each year from its budget to R&D activities. Our laboratories, laboratory devices, trained quality control and R&D personnel are proof of this.

Erse Kablo is the first and single company in Turkey, which, with ERVITAL fire-resistant cables, has successfully passed the system sustainability tests in accordance with DIN 4102-12 (E30 E90), in the laboratories of MPA NRW- is an internationally reputable organization- and obtained the VDF certificate.

DIN 4102-12 (E30 E90) fire resistance standard is an international criterion, which ensures function continuity. Its main purpose is to maintain the function continuity of the systems, which are of vital importance for people during a fire, such as emergency illumination, elevator and announcement systems.

In addition, it maintains the characteristics of a company having the widest scope in the sector, with certificates it has obtained for many products in its product range from internationally reputable organizations.

Although certification study has not been made by the English LPCB organization for the fire resistant cables, and license has not been given yet in Turkey, certification studies of the solar cables, which are solar energy cables, are currently ongoing.

In addition, as Erse Kablo, we have started the National Quality Movement and EFQM Perfection Model studies together with KalDer. At the moment, training process of our personnel is ongoing. We have designated the EFQM, long-running journey of seeking the perfect, as our Management Model and we are trying to spread it out to all our organization, in short, it will be the transformation-development practice of the company in the technical, administrative and managerial sense.

As the first fruit of this, we have got involved in the National Quality Movement, which is a long-running journey, and we have undersigned the National Quality Movement declaration of good intent with the chairman of the Board of Direcitors of KalDer.

-

What is RoHS-REACH compatibility?

RoHS is the directive accepted by the European Council, which stipulates the non-existance of certain substances in electronic devices or materials. It stands for (Restriction of Hazardous Substances Directive).

It prohibits the utilization of hazardous substances on human health, such as lead, cadmium, mercury and bromized components.

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is a policy of the European Union in respect of the chemicals, and stands for Registration, Evaluation, Authorisation and Restriction of Chemicals.

-

What is EMC?

EMC (ELEKTROMAGNETIC COMPATIBILITY): Ability of a system or device to execute its functions without being affected by the electromagnetic environment where it is placed in (without an irreparable electromagnetic impairment). A device should not disseminate unwanted electromagnetic waves to affect other devices in its vicinity, and also it should not get affected by unwanted electromagnetic waves disseminated by other devices.

One of the main factors designating the EMC quality is the cables connecting devices to each other. Because these cables both transmit the unwanted electromagnetic waves from one point to other (intervention by conductivity), and disseminate the signals circulating on them to their environment like an antenna (intervention by radiation).

Two main elements designating the cable performance are the screening material quality and cable screen earthing.

-

What is capacity? To what is it dependant on?

It is the electrical energy accumulated by the isolation material, and it is dependant on the conductor, isolation, isolation material, and dielectric constant. High-valued capacity is generally in poor property.

-

What is speed of spreading?

Speed of spreading of the cable, is the ratio of speed of the signal in the cable to the speed of light. For example, while the speed of spreading is %66 in solid PE isolated cable, it rises up to %87 in foam PE.

This property can also be shown as delay.

-

What does screening effectiveness? What are the effects of the materials used in screening performance?

Screening effectiveness is the ratio of the signal received without screening to the signal received with screening.

By using the data obtained from measuring procedures together with the mathematical formulations given in the below table, screening effectiveness is calculated in different frequency intervals.

Materials to be selected with the purpose of screening can be divided into three groups:

1) High-Performance Materials

Sealing made of the materials such as steel, copper, and stainless steel (80-120 dB screening effectiveness)

2) Standard-Performance Materials

Conductor metal layers (20-40 dB screening effectiveness)

3) Poor-Performance Materials

Metallized fabric structures, conductor paper materials (conductor polymers) (15-30 dB screening effectiveness)

40 dB screening effectiveness can solve many problems in practice.

In military systems, 100-120 dB screening effectiveness may be requested.

-

What does earthing mean? How is it made?

It is connection of an electric circuit or device to the earths surface, or to a reference surface in a size to substitute for the earth, with an interconnection, voluntarily or involuntarily.

Earths absolute reference is regarded as zero volts. In the real sense, all devices are obliged to be brought to this absolute zero point for an earthing.

Some of the structures, which can substitute for the earth in practice:

-Steel case buildings

-Vehicle body (automobile, aeroplane, vessel)

-Water pipes

-Earth electroded systems

-Earthing plate and case etc.

Since the cables are used in signal transmission between the source and the load, on which side earthing shall be made, and quality of earthing has a great significance. Unwanted electrical fields can be well-screened only on a cable, which is screened by load. However, this is not enough for screening of the magnetic fields. When earthing is applied on both the source and the load side, electric field screening is better and magnetic screening is ensured. (Screening effectiveness increases 10-20 dB)

By using flexible double conductors (by minimizing the fields between conductors and by ensuring the flow of opposite currents) magnetic leakage can be decreased. When earthing is applied from both sides, electrical and magnetic screening is ensured in an effective way.

-

What is characteristic impedance? What does it signify in Coaxial cables? To what is it dependant on?

On a transmission line, in an unreflecting condition, it is the ratio of amplitudes of voltage wave and current waveproceeding on the line.

Most common electrical property of Coaxial cables, is the characteristic impedance. It does not depend on the length. It depends on cable sizes and isolating material. It is signified in Ohm.

Coaxial cables are configured in 50 ohm, 75 ohm, and 93 ohm in general.

-

What does attenuation (dB/100mt) mean? Please give information briefly.

All the transmission lines or coaxial cables cause signal losses. In other words, during progressing of the signal in the cable, circuit or air environment, a decrease occurs in signal strength. These losses, which are named as attenuation, will decrease the efficiency of the transmission line, and and power capacity limits. They are signified as a ratio in decibel or in a logarithmic ratio.

On evaluation of performance of the cables in terms of attenuation, the attenuation constant is evaluated.

For a cable or other transmission environment, attenuation constant is the voltage or current ratio, which decreases in the direction of the signals way.

Its unit is decibel/unit cable length.

-

What does Return Loss (Reflection Loss) signify?

Cable sizes, quality of the insulating material, and errors occurred when laying the cable, affect the characteristic impedance. Every disorder and error causes reflections.

Return loss is the ratio between the output signal and reflected signal.

-

What is Exproof?

Exproof stands for Explosion Proof, and it means being protected against explosion.

-

What do the terms used in fire resistant cables signify?

FE 180

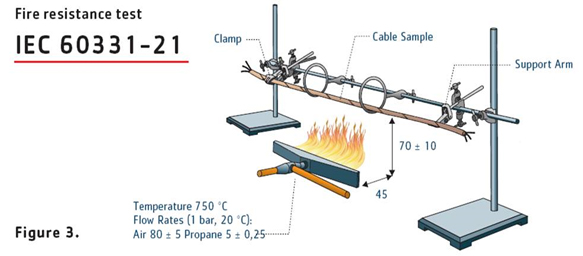

From the fire test made in accordance with IEC 60331 21 and 23 Standard, ensuring the current transmission of the cables for a period of 180 minutes (circuit integrity of the cable or or ability of the cable to carry the current within this period).

PH 30 60 90 120

From the fire test made in accordance with EN 50200 Standard, ensuring the current transmission of the cables for a period of 180 minutes for 30, 60, 90, and 120 minutes (circuit integrity of the cable or or ability of the cable to carry the current within these periods).

E 30 60 90

From the fire test made in accordance with DIN 4102 12 Standard, ensuring the current transmission of the cables for a period of 180 minutes for 30, 60, and 90 minutes (circuit integrity of the cable or or ability of the cable to carry the current within these periods).

CI

Abbreviation of the term Circuit Integrity, and the symbol used in fire resistant instrument cables.

-

What are the general characteristics of thermoplastic isolated and sheathed cables (TS EN 50525-1, VDE 0281/1), nominal voltage of which are 450/750 V?

Isolation:

Isolation should consist of the thermoplastic material type, specified for every type of the cable.

For the highest continuous conductor temperature 70 ºC, and for the cables isolated with PVC compound, TI 1, TI 2, TI 4, and TI 5 types are proper.

For the highest continuous conductor temperature 70 ºC, and for the cables isolated with PVC compound, TI 3 type is proper.

Sheath:

Sheath should consist of the thermoplastic material type, specified for every type of the cable.

» For PVC sheathed cables in fixed plants, TM 1 type is proper.

» For PVC sheathed flexible cables, TM 2 type is proper.

» For heat resistant, For PVC sheathed flexible cables, nominal conductor temperature of which do not exceed 90 ºC, TM 3 type is proper.

» For oil resistant, PVC sheathed cables, TM 5 type (H05VV5» F,H05VVC4V5» K) is proper.

» For low temperature resistant, PVC sheathed cables, TM 6 type is proper.

Application:

As a homogenous layer, sheath is extruded;

a» on the core in single» core cables

b» on the core assemblage and fillings, and inner cover if any, in multi» core cables.

-

What is critical frequency?

Coaxial cables are especially used in high frequencies. But there is an upper limit for the frequency field; this limit is defined as the critical frequency. The cable should not be used above this limiti.

Taking into consideration that, average diameter of the cable is

This frequency is given as below.

.

.

If magnetic permeability is equalized to 1,

.

.

But there is another limitation in respect of high frequency. In high frequencies, the cable should not be bended too much. Ampirically, bending radius of the cable should not be greater than the wavelength of the signal in the cable.

-

What is Construction Products Regulation (CPR)?

Regulation, which designates the procedures and principles on putting on the market and maintaining in the market the construction products, by constituting the performance descriptions in relation to the main characteristics of the construction products, and rules of putting CE mark on the products. nci ile ilgilenmekte ve kurallar gerekmektedir. Temel gerekliliği; yangın durumunda emniyet dokümanında bu kurallar açıklanmıştır.

-

What is the context of the Construction Products Regulation (CPR) about the cables, in relation to fire security?

CPR deals with the reaction of the cables to fire and their fire resistances, and it brings forth rules. These rules are explained in the safety document in case of fire.

-

Which cable products will the Construction Products Regulation (CPR) cover?

In reaction classification and ECa classification of EN 13501 electric cables, flame progression test is required in accordance with EN 60332-1-2. PVC based (halogenated) cables may fall into this class.

For us, it covers all the cables. But there is still uncertainty on which cables will be used in closed areas of constructions. Standards have not been published yet.

rinin (kablo) verilen bir sürede operasyonu devam ettirebilmesi (devre bütünlüğü)

-

What are the constructions in which fire resistant cables are used?

- Hospitals

- Schools

- Shopping centers

- Cinema and theater halls

- Metros and road tunnels

- Airport terminal buildings

- Hotels

- Tall buildings

- Community buildings

-

How will the implementation of the Construction Products Regulation (CPR) in the European Union and other countries? Which countries and when will start?

Cabling performance declarations and CE marking became compulsory on 1 July 2017 in the European Union.

-

Case study for a country where the classification is defined, which class will be applied where?

In construction works, the use of the cables which provide the reaction of fire performance in different parts of the structures is determined by regulations and laws. In our country this task was given to the Ministry of Environment and Urbanism. In this context, revisions in the CPR extent should be made in the regulations concerning the protection of buildings from fire in the sections related to electrical installations and cables. The consciousness of the persons and institutions providing the engineering services, making the right decision in selecting the material will prevent possible loss of life and property that may occur in the following periods and prevent possible legal sanctions.

Although the declaration of which cable to use is not officially made by the Ministry until this date, some contracting and project firms have published articles on this subject and have been in some requests on their specifications.

-

What do Reaction to Fire, and Resistance to Fire mean?

» Reaction to Fire: Contribution of the construction products (cables) on spreading of fire.

» Resistance to Fire: Ability of the construction products (cables) to maintain the operation for a given period (circuit integrity)

-

What is Reaction to Fire Classification (Euroclasses) of Cables?

Common European classifications in relation to flammability properties of the construction products. (EUROCLASSES) (EN 13501-1)

-

What are the standards in relation to Reaction to Fire Classification of Cables?

» EN 50399

» EN 13501-1

» EN 60332-1-2

» PrEN 13501-6

» EN 610034-2

» PrEN 50575

» EN 50267-2-3

-

What are the standards in relation to Resistance to Fire Classification of Cables?

» EN 50200

» IEC 60331 serisi

» EN 61034-2

» EN 50362

» IEC 60331-1

» EN 50267 serial

» IEC 60332 serial

» IEC 60331-2

» EN 50289-4-16

» EN 50577

-

Within the context of the Construction Products Regulation (CPR), how is the third party certificate and CE marking currently being made, and how will it be after the new Construction Products Regulation (CPR)?

For the cables, currently, declaration of conformity is being prepared and CE mark is put in accordance with the low voltage directive. While the declaration of conformity is being prepared, cable production standards are being specified.

» The cables should be certificated by the certification bodies.

» Instead of the CPR declaration of conformity, the declaration of conformity, which defines the performance that the product will show when used in the construction, is being used.

» Cables should be certificated within the context of the standards, which are in conformity with the low voltage directive, and if the cables are fire resistant, they should be subjected to fire resistance tests and certificated.

» Reaction to fire classification of the cables should be made by the certified body.

» After these approvals and certifications, performance description is published and CE mark is put.

-

How will the timing of implementation of the Construction Products Regulation (CPR) be in European Union and other countries?

In which countries and when will it start?

CPR has entered into force on 1st July 2013 mandatorily. But theres still a gap on the harmonized standards. For example: EN 50575 and EN 13501-6 will be published in draft and approximaletly in February 2014. Consolidation of the system may stretch out to 2015.

-

Case study for a country, for which the classification is defined. Which class will be implemented where?

Each country will determine the performance classification on the cables itself, but from the viewpoint of Turkey, classification, which gained recognition in Europe, shall be taken as an example.

Our opinion: No cables other than A1 , B1ca B2ca , C and D classes should be used in closed sections of the constructions.

-

What will the greatest changes in the cable market be with the Construction Products Regulation?

CPR is a mandatory implementation. Every country to give products to European Union countries, should meet the CPR conditions.

-

What are the materials used in cable production? What are their properties?

What is the importance of the materials used, in cable selection, and in which fields are they being used?

Although many different materials are being used in cable production, most widely used materials are those below:- Polyvinylchlorur (PVC) based materials

- Polyethylene (PE) materials

- Materials not containing halogene, and materials with low smoke density (HFFR-LSOH)

- Materials providing fire resistance

a) Properties of Polyvinylchlorur (PVC) based materials:

PVC (Polyvinylchlorur) is a material widely used in cable isolation and sheathing. It is being preferred since it is cheap and easily applicable. It has flame-retarding property in its nature. Although flame-retarding property can be developed with additive agents, it emits intensive smoke and corrosive gases during fire. As it might be expected, intensive smoke will make difficult the evacuation of people and operations of extinguishing and rescue teams.

HCl, CO2 and CO gases, which come into view as a result of burning of the PVC based materials, are the primary death causes of people. Hydrochloric acid, which emanates from integration of HCl gas with water, rapidly corrodes metal construction elements and electronic devices. It has been allowed for in the areas, which are specified to be implemented by our technical team within the context of the project.

b) Properties of Polyethylene (PE) materials:

Polyethylene material is a material, chemically without halogene. When burned, it doesnt emit poisonous and corrosive gases, but since it doesnt have flame-retarding property, and since it is easily inflamed, it contributes to spreading of fire. Its smoke intensity is above the limit values.

Because of these reasons, cables made of polyethylene material should in no way be used in the construction.

c) Properties of HFFR (LSOH) materials:

It is flame-ratardant, in case the fire source is drawn away, and in case fire is extinguished, inflamed cables automatically die down.

In case of fire, they dont emit corrosive and poisonous gases. This property is primarily important for human life, and they dont cause corrosion in electrical and electronic devices.

It has low smoke intensity. Low smoke intensity is important from the viewpoint of evacuation of people from the fire location and fire extinguishing operations.

d) Properties of fire resistant materials:

Fire resistant materials are especially used in core isolation of the cable. The reason of this is no doubt the fact that cable cores bear the electric current.

Besides, in order to increase the fire resistance of the cores, protective bandages and sheaths are also being used.

Below materials are being mostly used today.

In cable isolation;

1) Polymer compound in cross-linked form, is a silicone based isolation material. It successively passes the standard burning tests.

2) Mica tape + XLPE or cross-linked HFFR compound is rather being implemented in power cables.

Glassfiber tape or mica tape is being used as a flame barrier on the cores in the cable.

-

Can you give us short information on the areas of utilization of your product groups?

Areas of utilization of Ervıtal fire resistant signal control cables:- In Closed Environments Where People Appear Intensively

- In Instrument and Control Engineering

- In Industrial Electronics

- In Indoor Communication Systems

- In Safety and Fire Warning Systems

- In All Constructions Where Human Life and İmportant Materials are Necessary to be Protected

- In Computers and Office Machines

- In Indoor Sound Schemes

Areas of utilization of Ervıtal fire resistant energy cables:

- In Devices and Machines, which are Necessary to Operate During the Fire (Emergency Elevators, Fire Water Systems etc.)

- In Ventilation Systems Operating Connected to Fire Alarm Systems

- In Illumination of Fire Escape Routes

- In Emergency Power Supplies

- In All Constructions Where Human Life and İmportant Materials are Necessary to be Protected

Advantages

- Fire-Retarding Property

- Low Smoke Intensity

- Free of Poisonous and Corrosive Gases

- Isolation Resistance of 180 Minutes (Min)

Areas of utilization of Coaxial cables:

- They are used as a connection cable in indoor catv-cctv systems, and low attenuation requiring satellite systems. The HFFR cables, which have flame-retarding property as of their structure, are used in place where the smoke and corrosive gases emitted during a fire in environments where people are intensive (shopping centers, hotels etc.), are needed not to threaten the human life.

Areas of utilization of signal control cables:

- Where Electromagnetic Interventions and Interferences Exist,

- In Instrument and Control Engineering

- In Industrial Electronics

- In Computers and Office Machines

- In Indoor Communication Systems

- In Indoor Sound Schemes

- In Closed Environments Where People Appear Intensively (HFFR)

- In Places Where Human Life and İmportant Materials are Necessary to be Protected (HFFR)

Areas of utilization of Erflex command cables:

- In Instrument and Control Engineering

- In Energy Stations

- In Meassuring and Control Purposed Machine Production

- In Assembly and Production Lines

- In Places Where Mechanic Forcing is in Medium Degree

- In Closed Environments Where People Appear Intensively (HFFR)

- In Places Where Human Life and İmportant Materials are Necessary to be Protected (HFFR)

Areas of utilization of data communication cables:

- In Scada systems

- In water and natural gas distribution networks

- In electric production and distribution

- In fuel filling facilities

- In energy power plants

- In production lines

Areas of utilization of composite cables:

- They are used in short-range video, sound and signal transmission in closed-circuit tv and camera systems.

- These kinds of composite cables are being peoduced in different sequences according to their utilization purposes.

- In Closed Environments Where People Appear Intensively (HFFR)

- In Places Where Human Life and İmportant Materials are Necessary to be Protected (HFFR)

Areas of utilization of Silicone cables:

» In high temperature machines and environments

» In low temperature environments

» In iron and steel industry

» In glass industry

» In burners

» In heating and illumination systems

» In white appliances sector

Areas of Utilization:

» In chemistry industry

» In power plants

» In petro-chemicals industry

» In inner and outer environments; in dry, wet, and moist environments

Areas of utilization of building automation cables:

EIB-H(St)H:- In automation of illumination system

- In automation of security systems

- In automation of heating, cooling, and ventilating

- In automation of sound and image systems

- In automation of electric, water, and natural gas systems

NOTE: these types of cables are not proper as feeding cables and being used in underground installments.

Areas of utilization of announcement system cables:

In production and implementation of the cables, first of all, properties and production parameters of the raw materials have importance. Parameters should be in accordance with national and international standards, and provide flexible solutions in areas of utilization.

Areas of implementation and utilization of the cables in this group has a very wide range, and they continue to be the vital points of especially the developing technology and industrialization, and signal transporting and control mechanisms.

Please give us general information on instrument cables.

In todays world, owing to the fact that heavy industry facilities (petro-chemicals facilities, petroleum refineries, raw petroleum pump stations, natural gas pump stations, thermal power plants, hydroelectrical power plants, natural gas cycling plants, fuel filling facilities) have developed and passed on to automation system, standart instrument cables cannot meet the needs of these kinds of facilities.

For this reason, in these kinds of facilities and heavy industry enterprises, utilization of industrial purposed instrument cables has been an obligation.

Our company is making the production of these kinds of cables in accordance with internationally accepted standards, which we have also indicated below.

Besides, special designs are being made and produced according to private demands of our customers.

-

What are the standards, taken as basis in production of instrument cables?

- EN 50288-7

- PAS 5308-1

- PAS 5308-2

ISOLATION AND SHEATH MATERIALS STANDARDS OF THE INSTRUMENT CABLES

» EN 50290-2-21 PVC ISOLATION /EN 50290-2-22 PVC OUTER SHEATH

» EN 50290-2-23 POLYETHYLENE ISOLATION /EN 50290-24 POLYETHYLENE OUTER SHEATH

» EN 50290-2-29 XLPE ISOLATION

» EN 50290-2-27 HFFR OUTER SHEATH

» EN 50363-1 SİLİCONE CAOUTCHOUC ISOLATION

FIRE PERFORMANCE TEST STANDARDS OF THE INSTRUMENT CABLES

Isolation resistance (CI)

» IEC 60331-21/23

» EN 50200/BS EN 50200/VDE 0482-200

Flame retarding of cable harnesses

» IEC 60332-3-24 (CATEGORY C)

» BS EN 50266-2-4

» VDE 0482-266-2-4

» EN 50266-2-4

Flame retarding of a single cable or single-core cables

» IEC 60332-1-2

» BS EN 60332-1-2

» VDE 0482-332-1-2

» EN 60332-1-2

Smoke intensity test

» IEC 61034-2

» BS EN 61034-2

» VDE 0482-1034-2

» EN 61034-2

Corrosive gas determination test

» IEC 60754-2

» BS EN 50267-2-3

» VDE 0482-267-2-3

» EN 50267-2-3

Non-halogenatedness test

» IEC 60754-1

» EN 50267-2-1

» BS EN 50267-2-1

» VDE 0482-267-2-1

-

What are the standards used in conductor selection in instrument cables?

IN ACCORDANCE WITH IEC 60228; VDE 0295; EN 60228

» SOLID (CLASS 1)

» BENT (CLASS 2)

» FLEXIBLE (CLASS 5)

SELECTION CRITERIA OF CONDUCTOR STRUCTURE

» A) FLEXIBILITY

» B) CONNECTION TYPE

-

What are issues necessary to be paid attention for isolation materials?

» Electrical properties

» Temperature resistance

» Burning property

» Connection method

-

What do the cable structure definitions signify?

CORE: Consists of an isolated conductor

DOUBLE: Consists of bending of two cores

TRIO: Consists of bending of three cores

-

What are core color codings?

a) Indıvidual screenless and general screened cables

CORE: WHITE Each core enumerated in regular turn

DOUBLE: BLACK / WHITE Each core enumerated the same

TRIO: BLACK / WHITE / RED Each core enumerated the same

b) Indıvidual and general screened cables

DOUBLE: BLACK / WHITE enumerated tape in doubles

TRIO: BLACK / WHITE / KIRMIZI enumerated tape in trios

Note: Core color-coding is being made in accordance with BS 5308.

-

For what purpose are shield and braid implemented, how are they signified?

Cables generally need an additional protection against mechanical effects to occur during laying and operating. These shields additionally function as earthing and screen saver.

» Steel tape shield (STA)

» Galvanized steel wire braid (SWB)

» Galvanized steel wire (SWA)

-

What do the codes used signify?

2Y: Polyethylene (PE)

2x: Cross-linked polyethylene (XLPE)

Y : PVC (70°C)

Yw: PVC resistant to 105°C

Yö: Outer sheath resistant to hydrocarbons and oil

Yv: Reinforced PVC Outer sheath

Yw: PVC resistant to 105°C

YY: Double PVC outer sheath

FRLS: Low smoke intensity PVC

H: non-halegenated (HFFR/LSZH/LSOH/FRNC)

HX: Cross-linked non-halegenated (HFFR/LSZH/LSOH/FRNC/resistant to oils and hydrocarbons)

2G: Silicone Caoutchouc (CI, fire resistant)

-

How are individual and general screens defined?

PIMF: Metal screened doubles (PSCR)

TIMF: Metal screened trios (TSCR)

GENERAL SCREENS (OSCR)

(St): Poliester laminated Aluminium tape + stannous copper earthing wire

(C): Copper wire braid

(St)C: Aluminium tape + stannous copper wire braid

(Cu B): Copper tape

-

How are metallic shields signified?

STA: Steel tape shield

Q/SWB: Galvanized steel wire braid

SWA: Galvanized round steel wire shield

-

What are our product groups used in Smart Buildings?

» Building Automation Cables

» Data Communication Cables

» Fire Alarm Cables

» Fire Resistant Ervital Cables

» Coaxial Cables

» Announcement Systems Cables

-

What do the colors preferred for outer sheath signify?

BLACK: UV resistance

BLUE: In EX-PROFF connections

ORANGE: In fire resistant products

GREY: In indoor environments

-

What do fire resistant cable and non-halogenated cable mean, and what are the differences between them?

These are cables, caryying energy and signal to emergency safety circuits, which absolutely need to operate for protection of life safety of people, valuable articles and devices, and for simplification of responding to fire, during a possible fire in constructions opened to public.

As required by their structure, HFFR (LSOH) cables can retard flame during a fire to start in the structure, they dont emit poisonous smokes and corrosive gases, their smoke intensities are low, but they cannot be used in the electrical circuits (emergency safety circuits) necessitating the continuation of their isolation. While the cables of these circuits have the characteristics of HFFR cables, they at the same time need to provide the continuation of their isolation for a certain period of time under fire conditions. They should carry the energy and signal for the minimum periods in the standards and regulations.

In our outcome projects, our fire resistant cables should be used in all areas necessitating current continuation during a fire; and our HFFR featured products, which do not emit poisonous and corrosive gases, should be preferred in the risky sections where the smoke can effect evacuation and human health negatively.

-

What should be paid attention to in fire resistant cable selection?

The most important issues in fire resistant cable selection, are that the cable has been certificated by a reputable certification body having international accreditation, and selection of cable proper to the fire resistance classification stipulated in sections or areas of the building/construct, in accordance with the criteria specified in the regulation on fire protection of buildings.

-

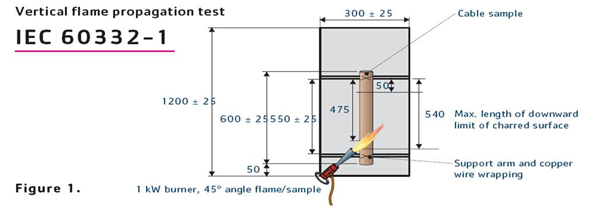

What are the fire performance tests applied to fire resistant HFFR-LSOH-FR cables?

- Resistance to vertical flame propagation test for isolated single conductor or cable

IEC 60332-1-2/EN 60332-1-2

It is the test by which flame retarding of the cable is tested. Flame is applied on the cable with an angle of 45 degrees. When theres not a carbonization from upper end of the cable to at least 50 mm down, the cable is deemed to have passed the test.

Cables outer diameter (mm) Flame application time (second) D<25

60

25 120

50 240

D>75

480

- Vertical flame propagation test in vertically mounted, bunched wires or cables

- IEC 60332-3-22 /EN 60332-3-22 7 liters/meters 40 minutes (CAT A)

- IEC 60332-3-23 /EN 60332-3-23 3,5 liters/meters 40 minutes (CAT B)

- IEC 60332-3-24 /EN 60332-3-24 1,5 liters/meters 20 minutes (CAT C)

- IEC 60332-3-25 /EN 60332-3-25 0,5 liters/meters 20 minutes (CAT D)

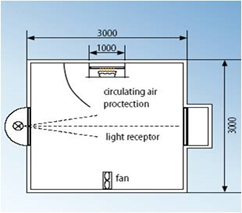

- Measuring of smoke intensity of cables burning under specified conditions

- At a volume of 27 m³; it is the test, by which the smoke intensity propagated from the cable during a fire, depending on the light transmittance. At the end of the test in accordance with the standard (Maximum 40 minutes), light transmittance should be minimum %60.

IEC 60754-2/EN 50267-2-2

Temperature :950 ºC

Time :30 minutes

Ph : shouldnt be less than 4,3

Conductivity : shouldnt exceed 10 µS/mm

It is a test, which ensures measuring of acid, gas and conductivity values propagated during burning. Conductivity value of 1 liter of gas solution constituted as a result of burning should be at least 10 µS/mm, and its pH ratio should be over 4,3. When these conditions are provided, the cable is deemed to have passed the test.

-

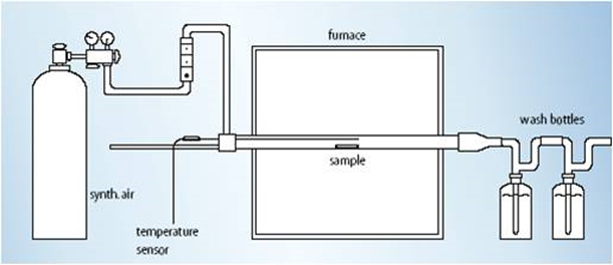

Circuit Integrity Test under Fire Conditions

EC 60331-21 / IEC 60331-23

It is a test, which is horizontally laid, and current transmission property under a fire at 750 °C is tested. With the FE (FE 180 etc.) value specified on the cable, minimum period that the cable resists to fire is given. .

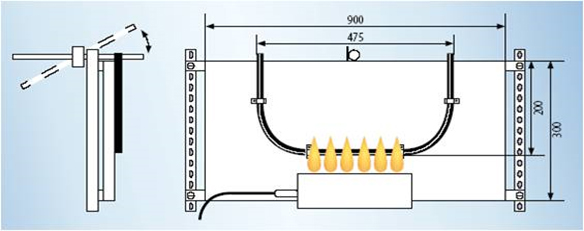

- Fire resistance test of unprotected small sized cables (with a diameter less than 20mm) used in emergency safety circuits. (MECHANICAL SHOCKED CIRCUIT INTEGRITY) EN 50200

- Fire resistance test of unprotected big sized energy and command cables (with a diameter greater than 20mm) used in emergency safety circuits (Mechanical Shocked Circuit Integrity)

This test, which is applied to cables with a diameter less than 20 mm, is the test in which circuit integrity is ensured by resisting to a fire at 830 °C, and 25 kg of a mechanical force in every 5 minutes. PH value (PH 30,PH 60, PH 90, PH 120) specified on the cable, give the minimum time period in which the cable can operate under these conditions. When the specified time period has elapsed, if there is no breakage or short circuit on the cable, the cable is deemed to have passed the test. In addition, test conditions can be improved with water spraying mechanism.

IEC 60331-2/ EN 50362

Conditions of the test applied to cables with a diameter of less than 20 mm, are exactly valid. That is to say, there is no change in applied temperature and mechanical shock values. Only by using a system proper for the cables with a diameter of greater than 20 mm, testing of big sized cables is made possible.

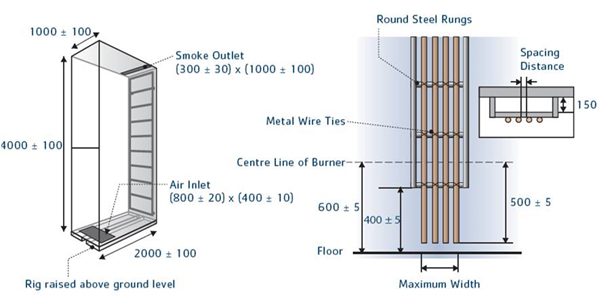

IEC 60332-3-22/IEC 60332-3-24/EN 60332-3-22/EN 60332-3-24

It is the test, by which flame propagation of the cable is tested in bunches. It is named under 4 different categories, depending on flammable material amount in one liter/meter. These categories are

27 m³ hacimde; yangın sırasında kablodan çıkan duman yoğunluğunun ışık geçirgenliğine bağlı olarak ölçüldüğü testtir. Standarda göre test sonunda ( Maksimum 40 dakika) ışık geçirgenliği minimum %60 olması gerekir.